Cooling Off a Hot Mess: South Researchers Test Ways to Make Asphalt Production Safer, More Environmentally Friendly.

Posted on January 24, 2019 by Bob Lowry

Dr. Shenghua Wu’s idea of a memorable road trip might be a little different than yours.

“I asked students in my Pavement Design course to write a one-page story about his or her most unforgettable field trip and what kind of pavement they saw,” said Wu, an assistant professor in the department of civil, coastal and environmental engineering at the University of South Alabama.

So when one student wrote about his trip to the Smoky Mountains, you read about the quality of the asphalt on the Blue Ridge Parkway. Another student who journeyed to Illinois discussed the pros and cons of the concrete interstates.

“Their stories are so interesting, and somehow you feel so close to them because all of us see the pavement every day; however, not everyone knows much about it,” Wu said. “For example, what is underneath the pavement, why are there so many cracks on pavement, why is the drive so smooth on asphalt pavement and can we use any recycled materials in pavement, etc. Those spontaneous questions, in my mind every time I drive, have motivated me to explore the pavement to a greater extent.”

Wu’s road to discovery has driven him to explore the feasibility of lower temperatures in the production of asphalt. He was a lead researcher for a National Cooperative Highway Research Program project that investigated the long-term field performance of warm mix asphalt technology from 2011 to 2016 at 28 test sites nationwide. Wu said it’s a sustainable and green asphalt technology, but its long-term performance is uncertain. The potential, however, is obvious.

“More than 90 percent of U.S. roads and highways are paved with asphalt, and more than 95 percent of roads in Alabama are asphalt pavement,” Wu said, adding that asphalt pavement construction needs production temperatures as high as 320 degrees.

“We have been investigating warm mix asphalt technologies that can reduce the production temperature by 20 to 70 degrees,” Wu said. “The reduction of temperature has many benefits. It can save fuel consumption, reduce greenhouse gas emission, create a much better working environment and extend paving seasons.”

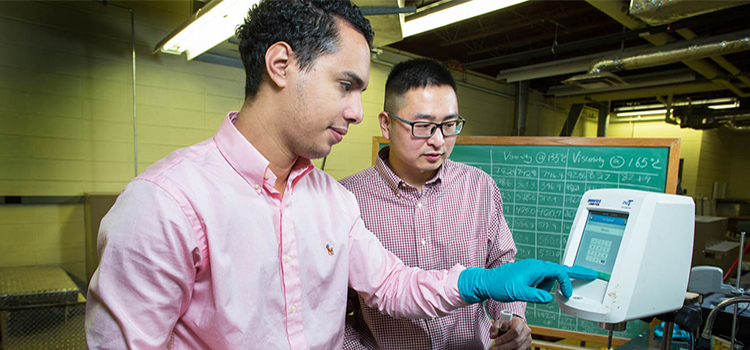

To assist his and his students’ research, Wu developed an asphalt laboratory last fall when he joined USA, with support from department colleagues and chair Dr. Kevin White as well as some undergraduates who helped set up all the equipment, which Wu believes is good training for them. “The students get the first-hand experience from how to assemble equipment to how to conduct an experiment, which can shape their learning horizons with a more specific skill,” he said.

Essentially, Wu said, warm mix asphalt is achieved in three ways; add a wax additive such as Sasobit, add chemical additives such as Evotherm and add water to make foam “like a cappuccino” to reduce the viscosity (thickness or stickiness) of the asphalt.

“In our lab, we can blend the different additives with asphalt using a high shear mixer and then measure the viscosity of blended asphalt using a rotational viscometer. The rotational viscometer will give us the viscosity values measured at different temperatures, so that we can determine the mixing and compaction temperature of the warm mix asphalt,” Wu said.

Omar Tahri is a civil engineering junior from Morocco. He works side by side with Wu in the asphalt lab. “It’s really nice to be hands on with materials that you are making predictions about and see your ideas become reality,” Tahri said. “I have enjoyed working with mix asphalt especially. I would like to continue my research on it once I graduate and begin my master’s degree.”

Warm mix asphalt research is integrated into each student’s laboratory experience in Wu’s materials lab course. Each group of students conducts viscosity tests and compares findings with other groups to see which technology can benefit mixing and compaction temperature the most.

Wu’s personal journey is just as interesting as his research. Born and raised in the Hunan Province of south central China, he came to America to get his Ph.D. in civil engineering at Washington State University. A first-generation college student, Wu was also the first in his family to come to the United States.

“I love travelling and I always took advantage of my spare time to go to different cities and countries when I was in college. I very much enjoy experiencing different cultures, beliefs and life in the vast world,” he said. “That seed of enthusiasm in experiencing life has been rooted in my body, and eventually it bloomed when I landed in the U.S. to start the new journey to explore a different world.”

Prior to coming to South, Wu was a senior sustainability research engineer at the Illinois Center for Transportation at the University of Illinois at Urbana-Champaign. Wu has LEED AP certification, meaning that he specializes in “green” building and construction sustainability.

“I am in favor of integrating sustainability into pavement research as long as any sustainable practices do not compromise the pavement performance,” he said. “We are not purely pursuing environmental benefits, but we are looking at the entire picture by applying triple bottom-line principles (social, economic and environmental aspects) plus performance criteria to our pavement research.”

From conducting a comprehensive literature review, to developing a rational testing plan, to carrying out the experiment, Wu said his students gain unique research experience to translate a research problem into an implementable research plan, “which I think would motivate them to enjoy the fruitful results after many trial-and-error experiments.”

He believes a good work ethic can be enhanced during the research activity, as student researchers develop patience, persistence, professionalism and diligence. “I always share my research experience and story with students,” Wu said.

“I used to work in the lab 15 hours a day and every day, and it seemed to be painful and boring at the beginning, which is quite commonplace for a researcher, but you know that once you survive, you grow to really enjoy the isolation and challenge, and it brings you a long-term positive impact on your own career. I encourage my students to develop and carry those good ethics to their future careers, which will pave their way to success.”

Yes, pave their way to success.

-

Dr. Woods and Dr. Wu honored by MACE awards

This year, two prominent faculty from the College of Engineering are r...

March 3, 2025 -

Launching a Career

Launching a Career...

August 8, 2024 -

USA Engineering Professor Receives New NSF Grant for Novel AI Computing Systems

A new $275,000 project entitled "Carbohydrate Memristor Empowered...

August 13, 2024 -

South Launches New Faculty Ambassador Program

South Launches New Faculty Ambassador Program...

July 30, 2024