Developing a Printer Worth Its Salt

Posted on February 5, 2019

Research on the synthesis and characterization of new ionic liquids for use as solvents and catalysts by Dr. W. Matthew Reichert, associate professor of chemistry at the University of South Alabama, reveals tremendous possibilities for a cleaner environment.

Ionic liquids are salts in a liquid state, and they are frequently referred to as “solvents of the future,” or “designer solvents” because of their potential to replace environmentally unfriendly liquids used to dissolve other substances.

Reichert has explored how ionic liquids could be used in the rapidly growing field of 3D printing, among other things. In 2017, USA awarded him a research and scholarly development grant to assist with starting his research.

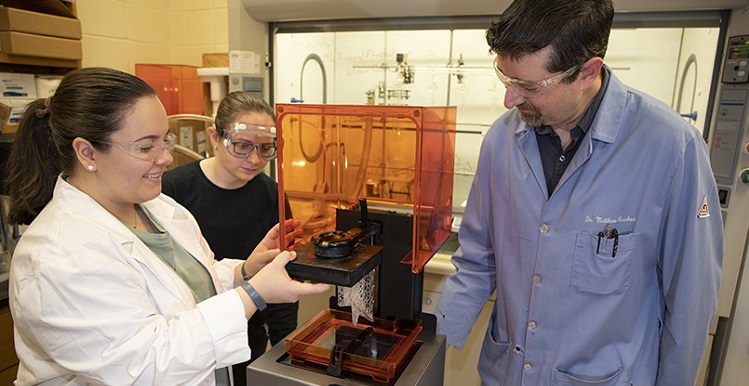

“We bought a 3D printer, then we started work,” Reichert said. “Two of the advantages of ionic liquids as additives to plastics we’re using is that they don’t leech out of the plastics, while providing the same advantages of traditional additives, such as durability and flexibility. The incorporation of ionic liquids into current additive manufacturing technologies can have a considerable environmental benefit, as well as an increase in consumer safety and product lifetimes.”

Reichert said the properties of ionic liquids will also make it possible for 3D printers to print a much larger variety of projects.

Presently, he’s writing a paper on his research, but he cautions there is still more research to finish before he gets marketable results.

Also, his research extends to making an easier way for fishermen to discover if they are fishing in waters with unsafe levels of heavy metals. Reichert hopes that research produces a test strip that can be dipped into questionable water. An ionic-liquid film would give fishermen a quick answer.

“The incorporation of ionic liquids into current additive manufacturing technologies can have a considerable environmental benefit as well as an increase in consumer safety and product lifetimes,” Reichert said.

Undergraduate students work on the research projects alongside Reichert. Madison McBroom, a senior from Huntsville, assists with the 3D printing, and Amanda Tanner, a senior from Cantonment, Fla., works on the heavy metal project.

“It’s wonderful to be able to get this experience before graduation,” said McBroome, who hopes to obtain a master’s degree in psychology and open her own office as a therapist.

“This work in the lab is important to me for my future studies because I’m learning a great deal,” said Tanner, who has applied to both graduate school and veterinary school.

Reichert, a Georgia native, came to USA in 2010, after conducting research and teaching at the U.S. Naval Academy for four years. His interest in chemistry began because he “had an excellent chemistry teacher in high school.”

In addition to his research of ionic liquids, Reichert is also president of the USA Faculty Senate, a position he will hold until April. He was also recently named as an assistant vice president for research, in addition to his faculty position.