Developing Next Generation Carbon Fiber Reinforced Polymers

Posted on February 22, 2021 by Lance Crawford

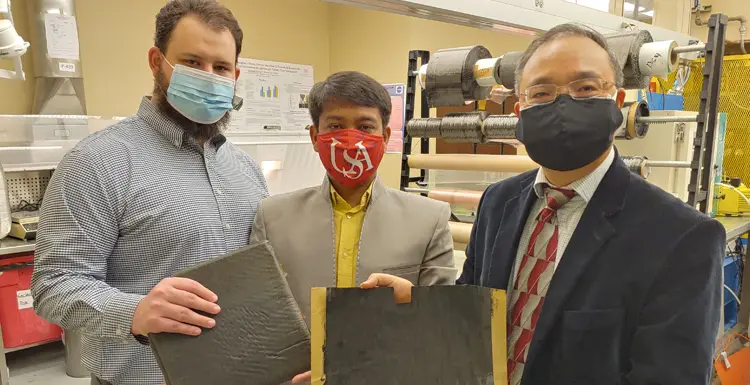

The University of South Alabama has received a $250,000 National Science Foundation Partners for Innovation grant to make next generation, high-performance carbon fiber reinforced polymer (CFRP) composites available for broad commercialization.

Conventional CFRP composites, usually in laminate form, provide an excellent weight-to-strength ratio but mechanical, electrical and thermal weakness limits their potential compared with metals in many applications.

This new technology has demonstrated notable improvements in those properties, allowing for far better multifunctional performance that can be better tailored to the applications. The key is the strong and highly conductive carbon nanofibers (CNFs) thread through multiple arrays of carbon fibers in a zig-zag pattern along what is known as the z-direction or thickness direction of a composite laminate panel, creating an interlocked multiscale fiber-reinforced network. This patented technology is known as ZT-CFRP and was developed by University of South Alabama mechanical engineering professor Dr. Kuang-Ting Hsiao.

“If you apply this concept, we can expect that airplanes, cars, or sporting goods utilizing ZT-CFRP will be more efficient, lower production cost, simpler to design and assemble, lighter and stronger,” he said. “The saved weight could be used for adding more performance or upgrading entertainment options.”

The National Science Foundation has long supported academic research, but its Partners for Innovation program focuses on identifying and supporting research and technologies that have potential for accelerated commercialization.

This required South to partner with industry. Five separate corporations have expressed interest in the project: Toray, a global leader in the supply of carbon fiber composite materials; Porsche Motorsports and MHP Americas, Inc., which are both subsidiaries of Porsche AG.; UST Mamiya, which makes graphite golf shafts; and Hexcel, a supplier of composite materials for Airbus.

“The success of this technology and its commercialization availability will potentially benefit all participating companies and the broader user base of composite materials,” Hsiao said. “If the technology demonstrates readiness for commercialization, the creation of a start-up, licensing, joint-venture, and other business arrangements in various markets all are possible next steps.”

The grant also includes a leadership component for students selected for the program.

South’s Leadership, Education and Development plan managed by Dr. Michael Chambers,

will be implemented for participating students and postdoctoral researchers. LEAD

will provide specific learning objectives and outcomes in the following targeted areas

of development: (1) Innovation and Entrepreneurship; (2) Commercialization and Technology

Transfer; and (3) Leadership.

-

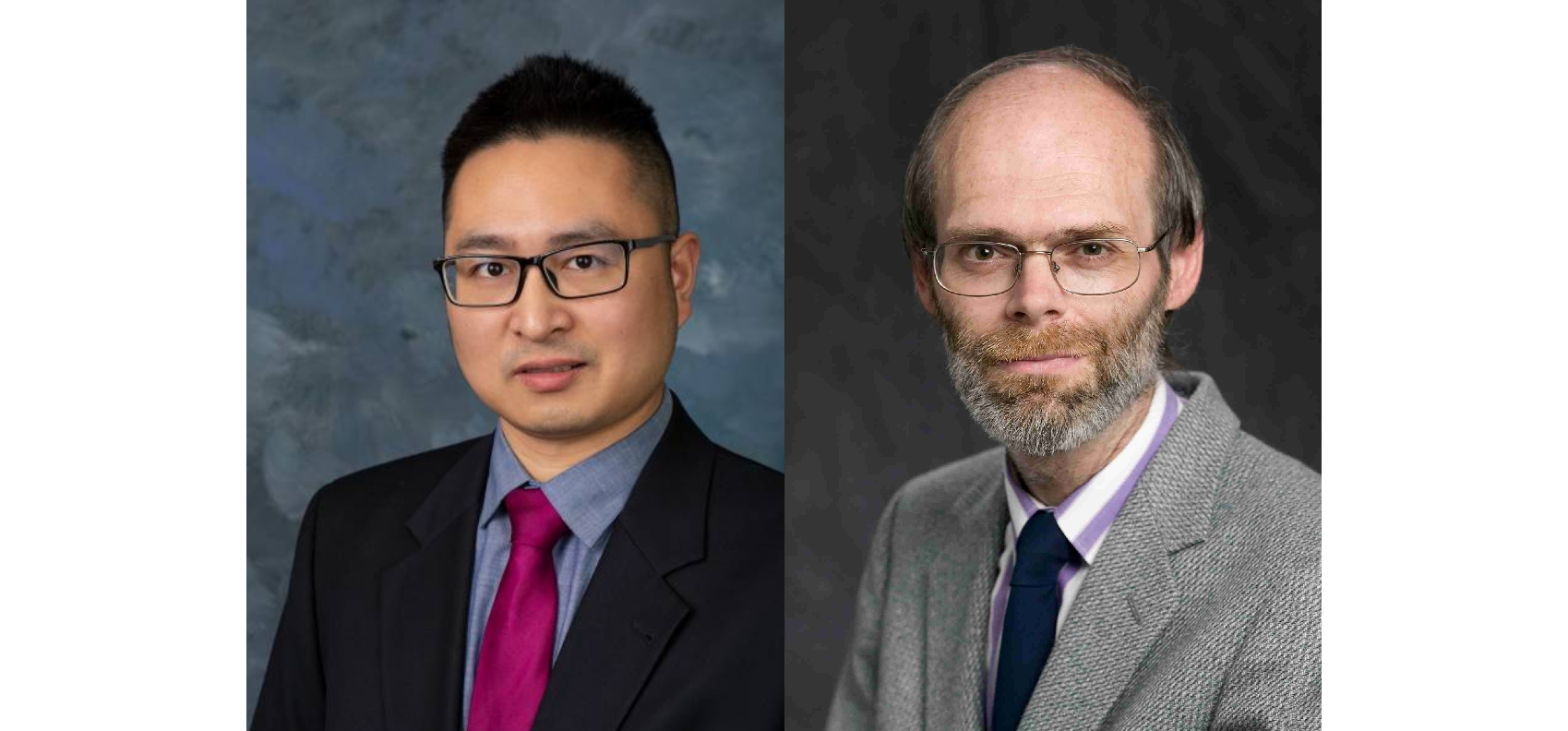

Dr. Woods and Dr. Wu honored by MACE awards

This year, two prominent faculty from the College of Engineering are r...

March 3, 2025 -

Launching a Career

Launching a Career...

August 8, 2024 -

USA Engineering Professor Receives New NSF Grant for Novel AI Computing Systems

A new $275,000 project entitled "Carbohydrate Memristor Empowered...

August 13, 2024 -

South Launches New Faculty Ambassador Program

South Launches New Faculty Ambassador Program...

July 30, 2024